If you are interested in green building, or call yourself a green building expert, then you should know about Mineral Wool insulation. If you have not seen Mineral Wool handled and installed, then you need to read this. If you think that Mineral Wool batts are similar enough to Fiberglass batts that you already know what you need to know about it, then you are a fool. And you still need to read this.

If you are a regular reader here you know I am an advocate of using Mineral Wool insulation to improve the energy performance of the way we build houses in the US. There are many reasons why I think Mineral Wool is the best insulation for us here. Recently I find myself making my case for this repeatedly, so, I thought it would be worthwhile to get it all down in one place and just point to it in the future.

So why am I constantly explaining why I like Mineral Wool, and what’s good about Mineral Wool, and no, that’s not what Mineral Wool is like – rather it is like this… It is because the green building community has almost universally decided that ole’ fiberglass batt insulation is BAD. There are good reasons for this, and we’ll look at those, but the more obvious question is what does this have to do with Mineral Wool? The overwhelming assumption among those interested in Green Building is that Mineral Wool is just like fiberglass batts, at least in all the ways they feel fiberglass batts are bad. So if fiberglass insulation is bad, then they are convinced that Mineral Wool insulation will be bad for all the same reasons. Its an easy conclusion to reach, but a lazy misunderstanding. The reality is that this is just not so. In fact this simply highlights the profound misunderstanding of what Mineral Wool insulation is like among green building advocates. The misunderstanding centers around the form of insulation – Batts. The green building community has been very quick to condemn “batts”, when the problems that concern them actually revolve around fiberglass batts.

Lets make this absolutely clear: There is Nothing wrong with insulation in the form of batts. Batts are a convenient way to package insulation for transport, handling, and installation, which is why it is the predominant form for insulation in the US. However there are legitimate reasons to criticize the fiberglass batt insulation which is the status quo in US house construction. Its a brief list of reasons, so lets look at them.

First, low insulation values. Thats right, fiberglass batts sold here in the US don’t provide as much insulation as they could. Its not that you can’t make fiberglass in higher performance levels, in fact it is made and sold in Canada at higher R values. But the big fiberglass insulation makers are not ready to bring that high R value fiberglass insulation here to the US. How do I know? I’ve called them, spoken to their people about it, they’ve told me they won’t bring the high R value insulation to the states even though I said I wanted to spec it. I say shame on them, we should all take our business elsewhere.

Second, Bad Installations. Bad installations mean sloppy fitting of batts into stud cavities, either over compressing the insulation or leaving gaps that allow convection, sloppy trimming around obstructions, and any number of installation sins that spoil the effectiveness of the insulation. The installers are only partly to blame. The material is limp, and fluffy, and because of this the handling, cutting, and placement requires more care to install well. It rarely gets that care, hence it is most often installed quickly and cheaply.

Third, bad air sealing, bad vapor retarder. Well what is that about anyway? Insulation is for insulating, not for air sealing? Well somewhere along the way somebody had the bright idea to combine a vapor retarder with a fiberglass insulation batt. It turns two construction steps into one, and in theory saves labor and so saves money. The problem is that once you’ve had a bad installation as noted above, and cut the vapor retarder around electrical boxes, what you end up with does not seal well nor retard vapor well. Hell, you say – I don’t need my insulation to make an air seal because I used that good ole’ house wrap on the outside. Nope, nothing wrong with house wrap, but no help with the air sealing you need at your vapor barrier. The air seal in this case wants to be on the warm side of the wall, to prevent interior moisture from entering the wall cavity and condensing during the winter heating season.

Lets summarize the lesson here. What most green pundits blame on batt insulation is the fault of fiberglass insulation. While Mineral Wool is also a batt, it is a completely different product with many different properties. It does not suffer from any of the above problems of fiberglass, yet retains the best part – its easy to handle, easy to install, and best of all your labor force already knows how to do it. That is no small point.

Ok, lets talk about Mineral Wool. I’m going to refer generally to “Mineral Wool”, but as of this writing I have in mind the product range of one manufacturer – Roxul. This is the only Mineral Wool manufacturer taking the residential market seriously in the US right now. Roxul sells their Mineral Wool in consumer friendly packages just as you would expect in a big box home improvement outlet. They are making their batts in sizes made to fit stud walls, clearly aimed at the market for building houses of wood, the very same market that fiberglass is sold to. This is important. Same kind of packaging, same kind of expectations, same kind of product experience – they are putting their product into long standing material streams that every builder in the US understands. Its available from the same sources, ready to be installed by the same people. There are other Mineral Wool manufacturers out there. They are not proactively pursuing the residential market. I’m not talking about them or their product. If your criticism of Mineral Wool revolves around your experience with some other product from some other time, then your concerns don’t apply here and now. You should catch up.

So lets talk about insulation value first. In batts offered for 2×4 stud walls Mineral Wool comes in R15, fiberglass comes in R11 or R13 (although it can be special ordered in R15 in the US). In batts offered for 2×6 walls Mineral Wool comes in R23, fiberglass comes in R19 (and again you can special order higher R value, but only R21). Furthermore Mineral Wool is available in batts that fit 2×8 framed walls, and these are R30. Fiberglass is not offered in batts for 2×8 stud walls. These are the products available now, today in Mineral Wool. If you are interested in maximizing the energy performance of your walls, its a no-brainer. Even if you changed nothing else about the way you build, you can improve the performance of your walls by switching to Mineral Wool.

Second, installations. You might think, how can Mineral Wool batts be easier to install than fiberglass batts? Its simple. Fiberglass batts are limp, soft, blankets. They have to be hung and stapled into place or they will slump and leave gaps. Mineral wool is dense, and firm, and friction fits into the stud space. People don’t generally understand this, and this is why I am including photos. Mineral wool has form, it has a shape. If you pick it up it does not drape or fold – it retains its shape. It is a block. This block when shoved into a wall cavity – and I say shoved because it literally must be pushed into place – when shoved into place it fills the entire wall cavity. No gaps, no sags, no spaces. More importantly no convection, no drafts, and no stapling.

This fellow is carrying a piece of mineral wool. Note it has a shape, and keeps its shape. This is nothing like fiberglass batts.

There is one caveat here. Just as with fiberglass, Mineral Wool must be cut to fit odd spaced studs and triangular corners that may result in framing. However this is much easier to do with Mineral Wool. With Fiberglass you are actually told, by experts, to use a 2×4 stud as a straight edge while you cut the fiberglass batts with a sheet rock knife. You are expected to compress the fiberglass enough to cut through it with the short blade of the razor blade. And if you are doing it correctly, you trim the batt and kraft paper to a different width to leave a tab so you can staple it up. Good luck.

Mineral Wool is easily and accurately cut with a large serrated knife.

Mineral Wool is different. You can actually measure, and cut Mineral Wool to size, like cutting a big block of wood. In fact for carpenters this comes as second nature, because as you might expect they are quite good at measuring, and then cutting something to fit, when that something has a shape and can be understood like a piece of wood. The cuts are made with large serrated knives – imagine a giant bread knife. So no compressing the insulation flat so you can cut through it. The Mineral Wool retains its volume while you cut through it with the long knife. You don’t cut against a 2×4, but rather you cut it on a purpose made cutting table which is just like a very large carpenters miter box. It adjusts for the thickness of the insulation, and allows you to set precise angles for cutting to fit those odd spaces.

This simple table makes cutting sizes to fit into easy work.

The Mineral Wool cutting table for me is the eye-opener, the cold water in the face that makes you realize that we never took insulation very seriously here in the US. Here we pull a 2×4 out of the dumpster, and use a razor blade holder to cut it on the floor deck. That’s the best we can do. Mineral wool is cut precisely to fill every void, quickly, accurately, providing complete fill of the wall cavity. Installs are easier, faster, better than fiberglass. I’ll say with some confidence that no other insulation product can fill a stud space so completely. No spray, no blown, no blanket can fill a wall void as well as a proper Mineral Wool installation.

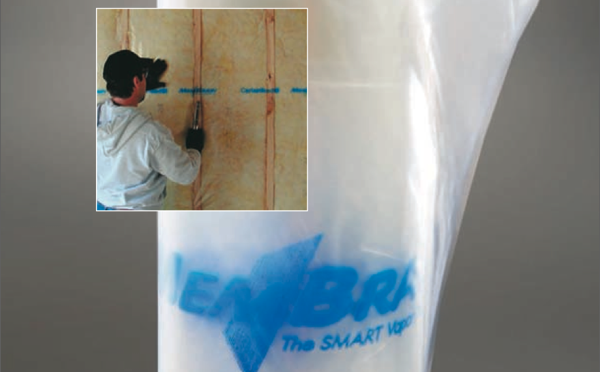

And third, air sealing. Mineral Wool only comes in un-faced batts. No foil or kraft paper vapor retarders are offered. This means an independent vapor retarder must be installed. Simply said, this is the best way to create an air tight envelope for the house. My favorite product in this regard is a variable permeability membrane, a so called “smart membrane” because the permeability self adjusts to suit conditions. An example is the “MemBrain” vapor retarder from Certainteed. This is their branding of the smart membrane product made by their European owner, Saint-Gobain.

Now if you wish to increase the likely hood that you won’t need to make any punctures in this air tight layer, then you should plan on a wall with an interior wiring chase, such as the USA New Wall that we’ve elaborated here. Your best chance for an airtight wall is if you don’t puncture your air barrier with electrical work, outlet boxes and switches. If you’ve not studied it before, when you are done here go read the USA New Wall article, and the Swedish Platform Framing article to see how all these come together to make a simple but high performance wall.

That covers insulation value, installation, and air sealing issues. Mineral Wool goes on to excel in other ways that contribute to my preference for this material.

Mineral Wool is hydrophobic. From the dictionary: tending to repel or fail to mix with water. If fiberglass insulation becomes wet, you end up with a wet lump of glass lint, with no insulation value to boot. Mineral Wool on the other hand will not become wet. Water in fact beads up and rolls off the surface of Mineral Wool. This promotes water draining and drying if the wall cavity becomes wet, rather than holding water like a sponge. Which would you rather have in your wall?

One of the big issues with improving performance of our walls is the thermal bridging of the wall studs. The most popular way to overcome this has been to install insulation on the exterior of the wall, continuously, to insulate the studs from the cold. The issue here is that rigid foam insulation has been the most common way to do this. The problem however is that the foam creates a vapor retarder, and the last thing you want is a wall with a vapor retarder on both faces. So the practice has been to make walls with exterior foam insulation without interior vapor barriers. The foam must be thick enough to prevent the interior of the wall cavity to allow condensation of the interior air. The problem here is that only the most general recommendations for these configurations can be made in the building code. Weather outside the given limits can result in condensation. Highly humid interior conditions can cause condensation. My opinion is that these walls are a disaster waiting to happen. The good news in this story is that Mineral Wool comes in configurations that can be used as exterior insulation in place of foam. These are very dense fiber panels that are strong enough to support siding and cladding material mounted over them in a manner similar to foam. The difference – Mineral Wool is vapor permeable which means you can insulate on the exterior without trapping moisture in the wall. Furthermore the insulation value of these dense Mineral Wool panels approaches the performance of foam. Typically for XPS foam you would get in the neighborhood of R5 per inch. The Mineral Wool will provide R4.6 per inch. And because of Mineral Wool’s hydrophobic properties it will not absorb moisture in this location, and in fact will promote the drainage and drying of rainscreen siding cavities. Foam insulation brings other problems, such as a dilemma in flashing practices, and the dubious reliance on adhesive tape as a long term weather barrier.

Last is Mineral Wool simply makes wood stud construction safer. This is the same material that is used to fireproof steel members in commercial construction. Mineral wool will stand up to temperatures that will reduce fiberglass to a puddle of molten glass. Mineral Wool will increase the length of time that a wood framed house will stand during a fire. It gives the occupants more time to exit safely, and firefighters a safer window of time to enter a burning home.

Lets just go over some broad conclusions now. Mineral Wool is a completely different material than fiberglass, they both just happen to fall in the broad classification of batts. Mineral Wool is available in much higher insulation values than fiberglass. Mineral Wool’s rigid shape and ability to be measured and cut accurately enables it to fill stud voids more completely than any other insulation product, with less effort, and more speed. Mineral Wool fits into the building practices of 99.9% of Americas’ builders with no need for new process, extensive re-training, or changes to new sub-contractors, new suppliers, and new business relationships. Mineral Wool is the easiest way for the vast majority of builders to step up their game and start building better.

—

Appendix 1: Concerns of Green Builders (Edit – nice thing about rants they tell me, you are free to go back and edit them. I wanted to replace the original discussion of cellulose which has been a distraction with information about formaldehyde and embodied energy which are concerns of green builders.)

Those focused on green building often immediately point to the presence of formaldehyde in binders in mineral wool. Formaldehyde based resins have long been used in the “glues” that prevent fibrous insulation from coming apart. Its long been used in fiberglass and is still in many fiberglass products today. But it is clearly on the way out. Fiberglass batts from Knauf and Owens Corning are now available with alternate binders. Mineral wool still contains a very small amount. The wall insulation products from Roxul meet the GreenGuard Children and School certification standard which means they are consistent with products that are used in schools, daycares or other environments where children spend significant periods of time. What this means is if you are a builder shifting from traditional fiberglass batts, this mineral wool will likely have less formaldehyde emissions than what you used before. If you are a green builder seeking to eliminate any formaldehyde, then you have other options.

On the matter of embodied energy, the Roxul products now use from 75% – 93% recycled content depending on the availability of the raw materials, and their facilities are zero waste to land fill. If you are a green builder that can get the same performance from a material with less embodied energy, then great. If you are a builder considering shifting from fiberglass, the energy savings from the lifetime performance of the mineral wool will greatly exceed any difference in manufacturing energy of the fiberglass you use now.

—

Appendix 2: Predictions. Higher R value insulation will eventually own the market here. Right now Mineral Wool is the only offering in these higher R values. Certainteed, one of the biggest US makers of Fiberglass is now owned by Saint-Gobain who is a large producer of Mineral Wool in the EU. They will almost certainly begin distributing Mineral Wool here. Owens Corning, the other large American insulation maker is highly vested in Fiberglass and will eventually begin offering the higher densities from the Canadian market here. But that may be short lived and I will not be surprised to see them turn to Mineral Wool as well. Fiberglass is a few short steps from being on the “known carcinogen” list, is currently classified as a “reasonably anticipated” carcinogen“. Removal of fiberglass may be the next big abatement industry. Mineral Wool on the other hand is widely available in the EU in what they call “biosoluble” formulas. These mineral fibers dissolve in contact with tissues, leaving no fibers to trigger disease. These formulas will come to the US as well which will solidify Mineral Wool as a healthy alternative to fiberglass. The writing is on the wall for these events. You can be the one to tell your friends and family you were the first to adopt Mineral Wool way back when in 2012.

Original Here:

What is the Greenest Insulation? The Case for Mineral Wool